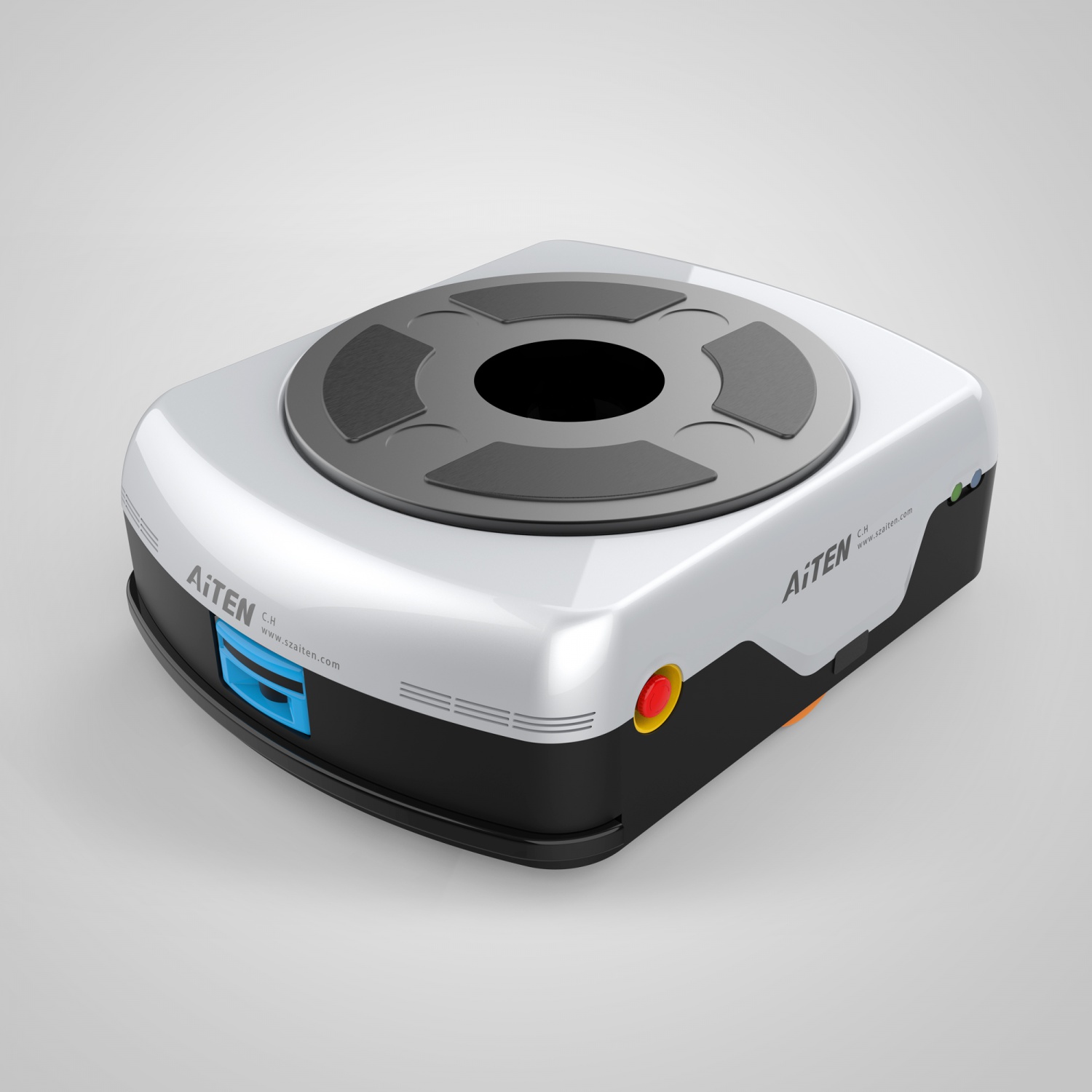

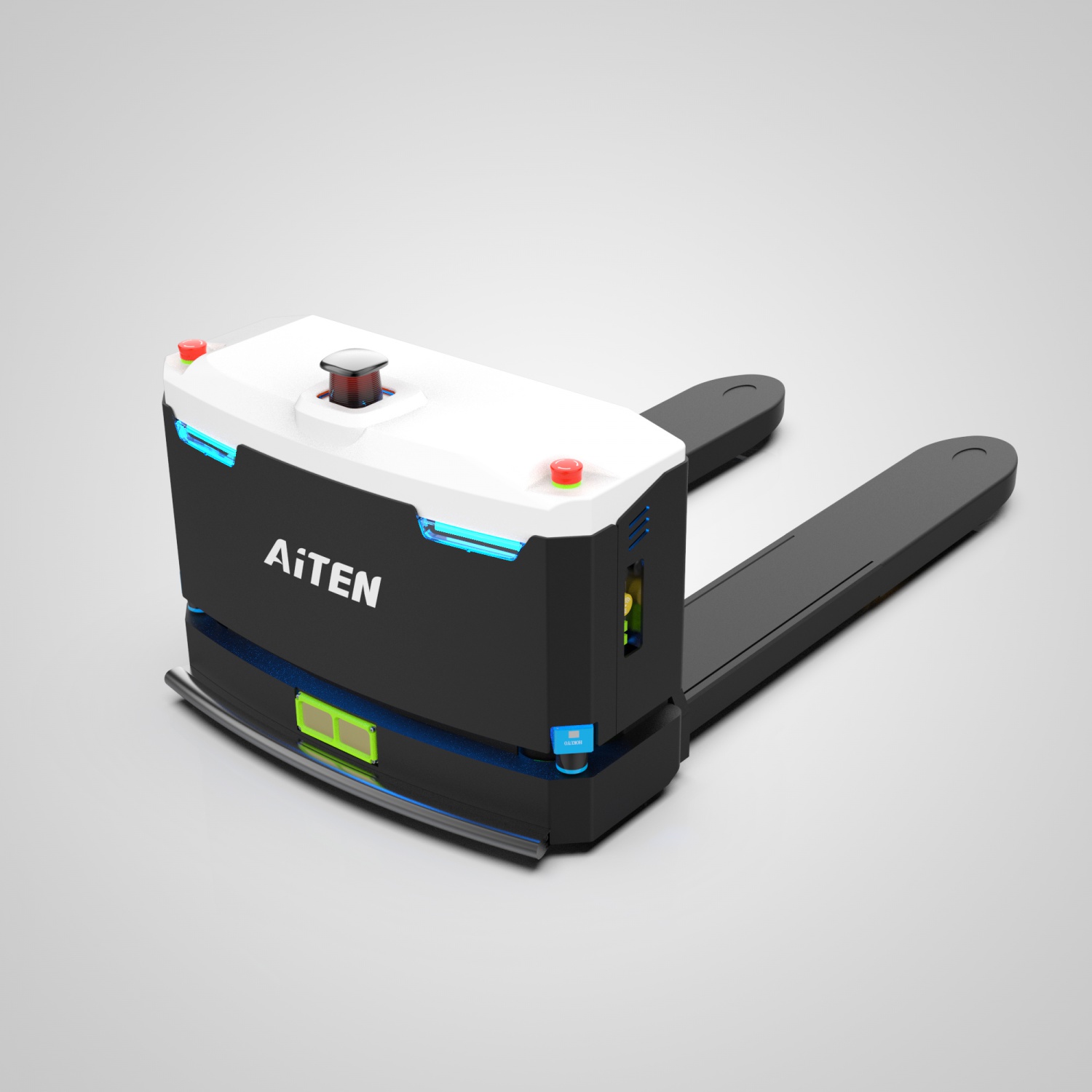

ATS Series Front-Towing Robotic Forklift Tugger

About the robot

| Robot name | ATS Series Front-Towing Robotic Forklift Tugger | |||

| Employment type | Full-time employees | |||

| Dimensions |

| |||

| Load capacity | 3000/5000 kg | |||

| The speed of movement | 2/1.5 kg | |||

| Energy consumption | ||||

| Working hours | 6 kg | |||

| The warranty period | ||||

| Power |

Relocatable robot

*Payment terms, contracts, shipping/logistics, insurance details, etc. are provided upon request.

ATS 30

- Dimensions: 1200 × 997 × 1850 mm

- Rated Load: 3000 kg

- Turning Radius: 1250 mm

- Ground Clearance: 52 mm

- Speed (no-load/full-load): 2 / 1.5 m/s

- Battery: 24V / 210 Ah

ATS 50

- Dimensions: 1845 × 997 × 1850 mm

- Rated Load: 5000 kg

- Turning Radius: 1250 mm

- Ground Clearance: 52 mm

- Speed (no-load/full-load): 2 / 1.5 m/s

- Battery: 24V / 210 Ah

Revolutionizing Logistics with the ATS Series Front-Towing Robotic Forklift Tugger

Smart Robotics for Seamless Operations

The ATS Series by AiTEN introduces a new generation of front-towing automated guided forklifts (AGF) designed to transform modern logistics. Built on a steering wheel chassis with a front-towing structure and powered by advanced laser SLAM navigation, these smart robots operate effectively in dynamic and complex industrial environments. With precision movement and autonomous control, they are the ideal robot worker for demanding logistical needs.

Efficiency and Automation in Every Movement

These logistics robots excel at point-to-point transport of heavy goods in trailers and storage cages, handling up to 7000 kg with ease. Perfect for warehouses, production lines, and distribution centers, the ATS Series supports both long-term automation and temporary task assignments. Whether you're looking to hire a robot for seasonal demand, rent a robot to scale operations, or invest in a robot for sale for permanent deployment, this solution is built for flexibility.

24/7 Productivity and Minimal Downtime

Designed for 24/7 unmanned operation, these warehouse robots eliminate downtime associated with manual labor and traditional equipment. With rapid 2-hour auto charging and up to 6 hours of runtime, they deliver consistent performance. Facilities in automotive logistics, e-commerce fulfillment, food and beverage distribution, and pharmaceutical warehousing can maximize efficiency through robotic process automation.

Intelligent Navigation and Collaboration

The ATS Series leverages AiTEN's proprietary RDS system for remote scheduling and multi-robot coordination. Smart obstacle avoidance is ensured with 360° LiDAR-based sensor fusion, making these robots in logistics safe and reliable in shared human environments. Predefined perception, deceleration, and stop zones offer proactive hazard detection, securing both cargo and personnel.

Unlocking Human Potential through Robotics

Deploying a robot worker in your facility means reducing unnecessary manual tasks, increasing productivity, and digitizing logistics workflows. This job for robots results in fewer errors, real-time inventory visibility, and faster material handling. Whether you're looking for short-term work for the robot or a long-term logistics automation strategy, the ATS Series adapts to your needs.

A Future-Ready Solution for Every Industry

From smart factories to large-scale warehouses, hospitals to retail distribution centers, the ATS Series sets the standard for logistics robots. As demand for logistics automation grows, integrating a reliable, intelligent warehouse robot is not just an option—it’s a competitive advantage.

Robots from the manufacturer

Robot for industry

- Automated

- Guided

- Vehicles

- (AGVs)

- Autonomous

- Mobile

- (AMRs)

- Logistics

- Warehouse

- Robotics