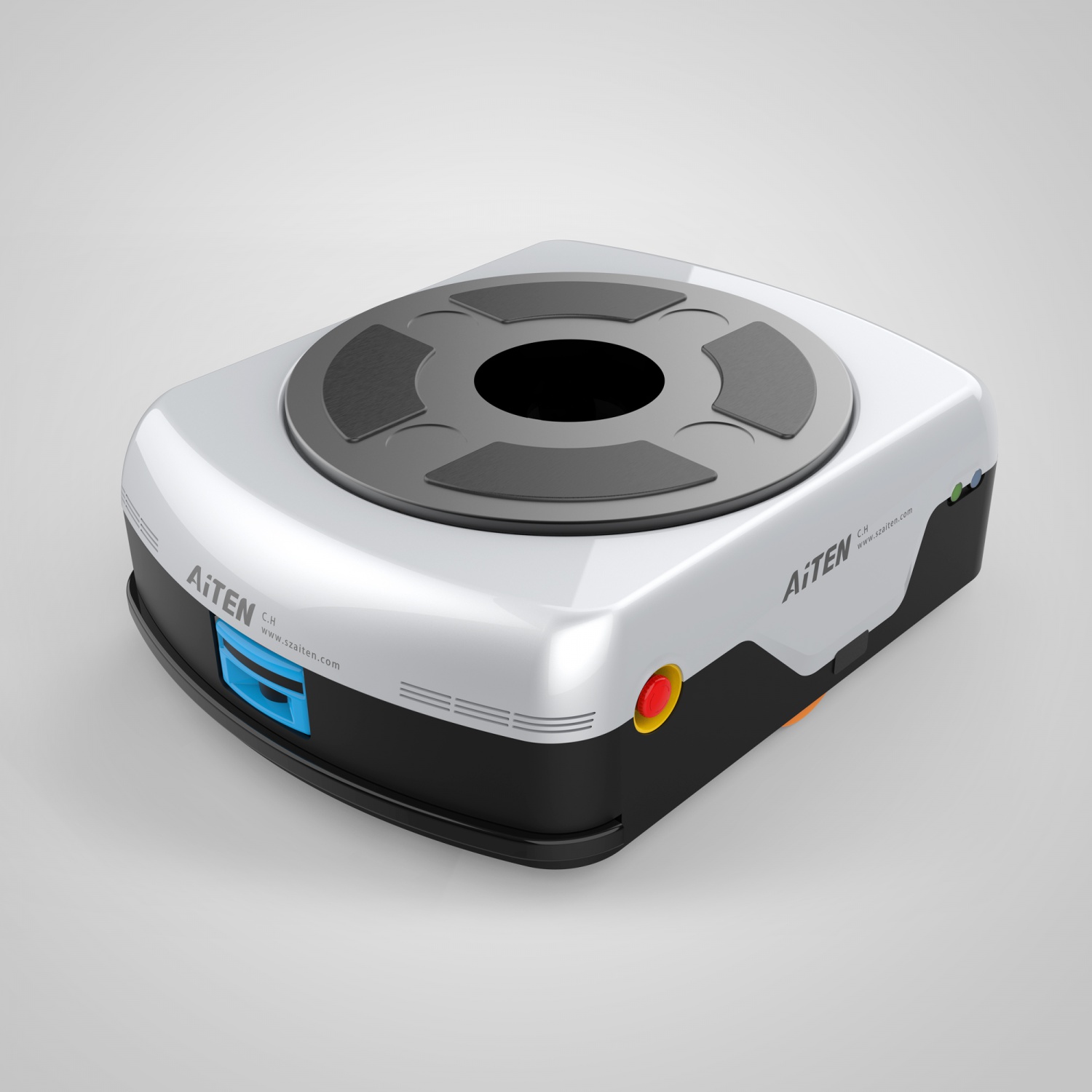

AMV10 Omnidirectional Guided Forklift

About the robot

| Robot name | AMV10 Omnidirectional Guided Forklift | |||||

| Employment type | Full-time employees | |||||

| Dimensions |

| |||||

| Load capacity | 1000 kg | |||||

| The speed of movement | 1.2 / 1.0 kg | |||||

| Energy consumption | ||||||

| Working hours | ||||||

| The warranty period | ||||||

| Power |

Relocatable robot

*Payment terms, contracts, shipping/logistics, insurance details, etc. are provided upon request.

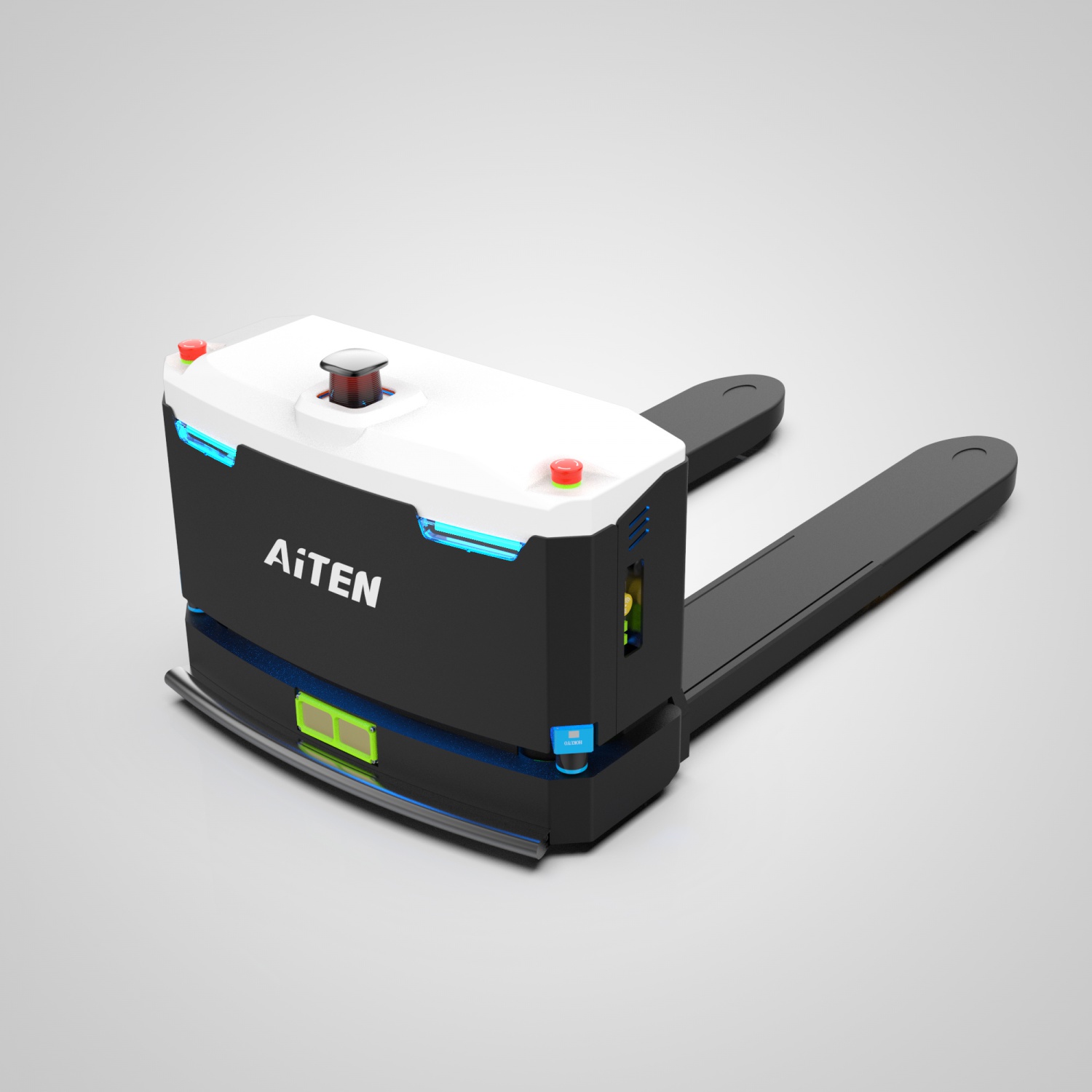

- Dimensions (L × W × H): 1580 × 790 × 1830 mm

- Fork Size: 205 × 60 × 1215 mm

- Rated Load: 1000 kg

- Wheelbase: 1250 mm

- Turning Radius: 1040 mm

- Right Angle Stacking Width: 2165 mm

- Lifting Height: 1000 mm

- Travel Speed (no-load / full-load): 1.2 / 1.0 m/s

- Battery Voltage/Capacity: 48V / 50 Ah

AMV Series: The Future of Agile Warehouse Automation

Omnidirectional Precision for Modern Warehousing

The AMV Series represents a quantum leap in warehouse automation technology, offering compact omnidirectional automated guided forklifts designed specifically for racking operations. These smart robots combine an innovative chassis mechanism with front steering wheel and rear dual differential wheels to deliver unparalleled maneuverability. Whether you need to hire robot solutions, rent a robot for seasonal demands, or purchase a robot for sale, the AMV Series provides the perfect combination of power and precision for today's dynamic logistics environments.

Revolutionary Movement for Complex Spaces

Engineered to outperform traditional AGVs, these logistics robots master narrow aisles as tight as 1.2 meters with an impressive turning radius of just 1,040mm. The AMV Series stands at the forefront of robotic process automation with its ability to handle 1000kg pallet loads while executing on-the-spot omnidirectional turns. Its adjustable fork size and expandable modular design make it ideal for diverse pallet handling applications in e-commerce fulfillment centers and manufacturing facilities.

Intelligent Features for Continuous Operation

Designed for non-stop productivity, this warehouse robot features rapid 2-hour auto charging for 10 hours of continuous operation. The advanced 360° LiDAR-based obstacle avoidance system and self-adaptive perception ensure safe navigation and accurate pallet identification. As one of the most capable robots in logistics for racking operations, it reduces unnecessary staff movement by 60% while boosting productivity by 30% - transforming operations in food & pharmaceutical warehouses and consumer electronics distribution centers.

Transformative Applications Across Industries

From automotive parts storage to chemical plant logistics, the AMV Series delivers exceptional value in pallet racking operations. Its compact 1580 × 790 × 1830 mm design proves particularly valuable in space-constrained third-party logistics facilities and FMCG warehouses. The integrated RDS (Robot Dispatch System) enables seamless multi-robot collaboration, creating efficient workflows that minimize risks associated with traditional forklift operations.

AiTEN Robotics: Pioneering Smarter Warehouse Solutions

Our AMV Series exemplifies our commitment to developing smart robots that redefine material handling. By combining omnidirectional movement with advanced laser SLAM navigation, we've created a logistics automation solution that transforms racking operations. Discover how our compact automated guided forklifts can optimize your warehouse workflows, enhance safety, and drive operational efficiency in today's competitive industrial landscape.

Robots from the manufacturer

Robot for industry

- Automated

- Guided

- Vehicles

- (AGVs)

- Autonomous

- Mobile

- (AMRs)

- Logistics

- Warehouse

- Robotics