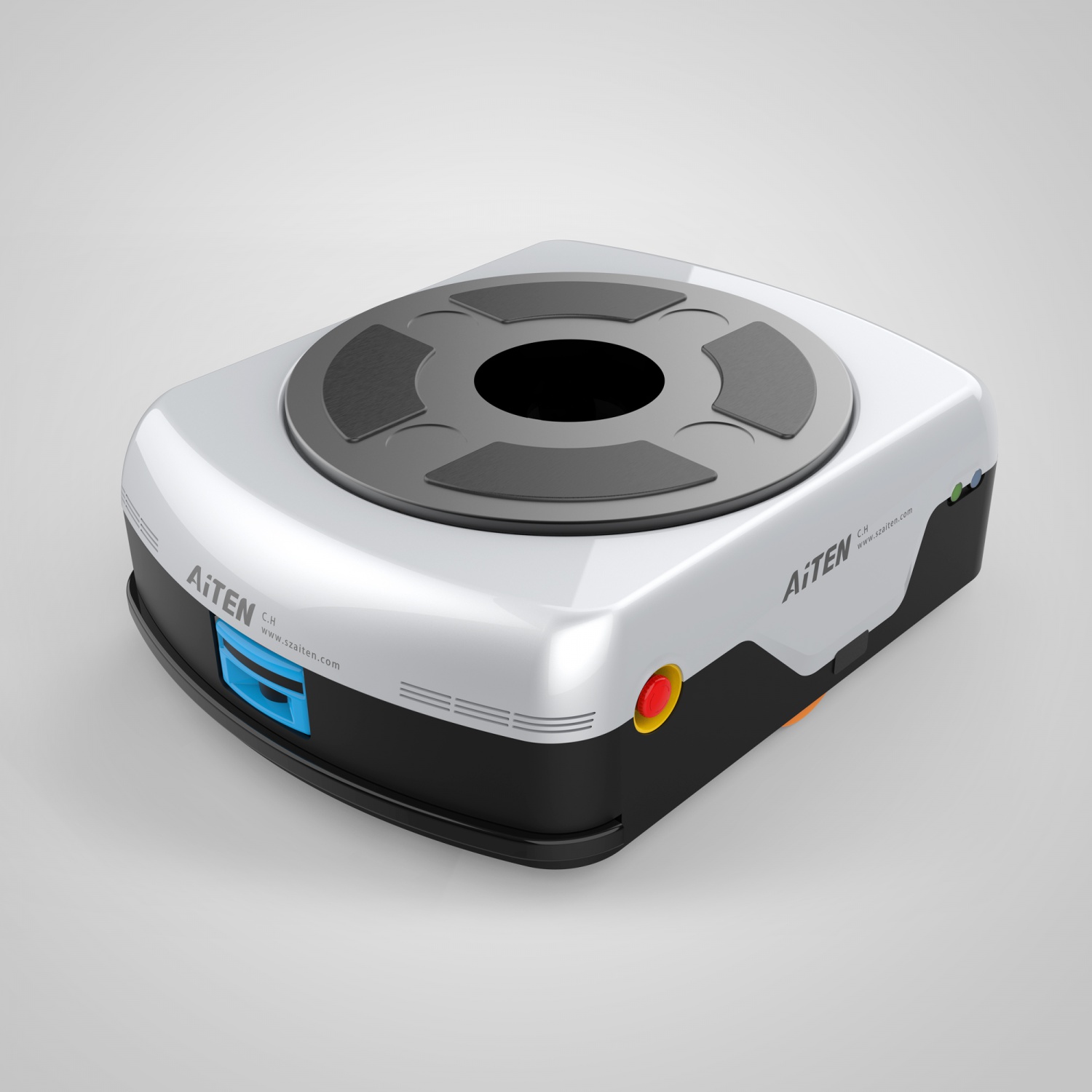

ALV03 Compact Robotic Guided Forklift

About the robot

| Robot name | ALV03 Compact Robotic Guided Forklift | |||||

| Employment type | Full-time employees | |||||

| Dimensions |

| |||||

| Load capacity | 300 kg | |||||

| The speed of movement | 1 kg | |||||

| Energy consumption | ||||||

| Working hours | ||||||

| The warranty period | ||||||

| Power |

Relocatable robot

*Payment terms, contracts, shipping/logistics, insurance details, etc. are provided upon request.

- Model: ALV03

- Dimensions (L×W×H): 1550 × 800 × 1605 mm

- Rated Load: 300 kg

- Fork Width: 1040 mm

- Minimum Aisle Width: 1325 mm

- Lifting Height: 600 mm

- Travel Speed (no-load): 1.0 m/s

- Battery: 48V / 50Ah

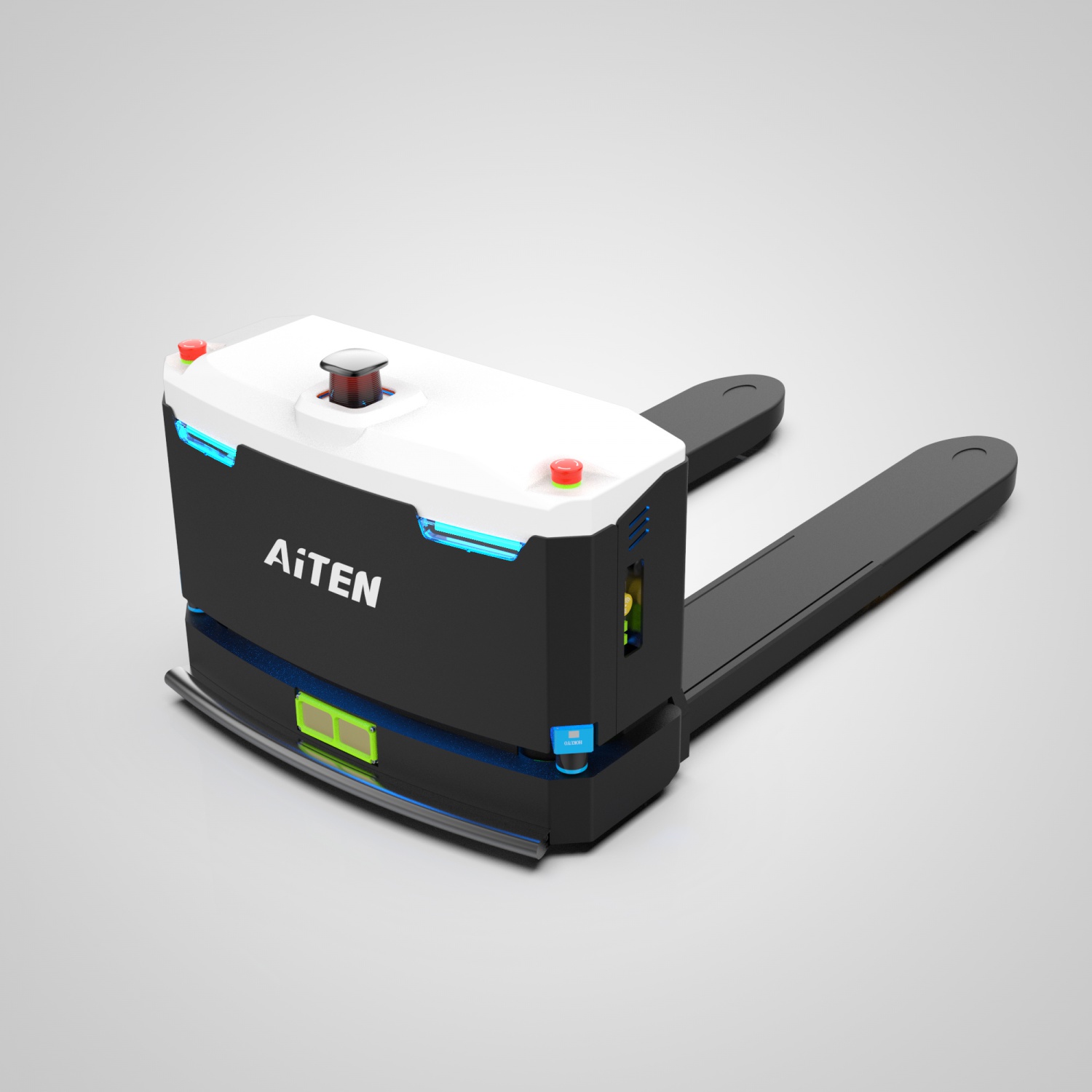

ALV Series: Compact Automated Guided Forklifts for Smart Warehousing

Revolutionizing Cage Handling with Agile Automation

The ALV Series represents a breakthrough in warehouse automation, offering compact automated guided forklifts specifically designed for handling storage cage goods. These smart robots combine a steering wheel chassis mechanism with advanced laser SLAM navigation to deliver unparalleled maneuverability in tight spaces. Whether you need to hire robot solutions, rent a robot for peak seasons, or purchase a robot for sale, the ALV Series provides the perfect balance of power and precision for modern logistics operations.

Precision Navigation for Complex Environments

Engineered to excel where traditional AGVs fail, these logistics robots master narrow aisles and complex L-shaped or S-curve pathways with ease. The ALV Series stands out in robotic process automation with its ability to handle 500kg cage loads while maintaining exceptional agility. Its self-adaptive perception system ensures rapid pallet identification, making it ideal for fast-paced e-commerce fulfillment centers and automotive parts warehouses where speed and accuracy are critical.

24/7 Performance with Intelligent Features

Designed for continuous operation, this warehouse robot features rapid 2-hour auto charging for 6 hours of uninterrupted runtime. The 360° LiDAR-based obstacle avoidance system and proactive prediction capabilities ensure safe navigation in crowded environments. As one of the most advanced robots in logistics for cage handling, it significantly reduces unnecessary staff movement by 60% while boosting overall productivity by 30% - a game-changer for third-party logistics providers and manufacturing facilities.

Transformative Applications Across Industries

From pharmaceutical cold storage to consumer electronics distribution, the ALV Series delivers exceptional value. Its compact design proves particularly valuable in FMCG warehouses with space constraints and chemical plants requiring precise material handling. The integrated RDS (Robot Dispatch System) enables seamless multi-robot collaboration, creating efficient workflows in food processing facilities and retail distribution centers alike.

AiTEN Robotics: Engineering the Future of Logistics

Our ALV Series exemplifies our commitment to developing smart robots that address real-world warehouse challenges. By combining cutting-edge navigation technology with robust construction, we've created a logistics automation solution that transforms cage handling operations. Discover how our compact automated guided forklifts can optimize your material flow, reduce operational costs, and future-proof your warehouse operations in today's competitive marketplace.

Robots from the manufacturer

Robot for industry

- Automated

- Guided

- Vehicles

- (AGVs)

- Autonomous

- Mobile

- (AMRs)

- Logistics

- Warehouse

- Robotics