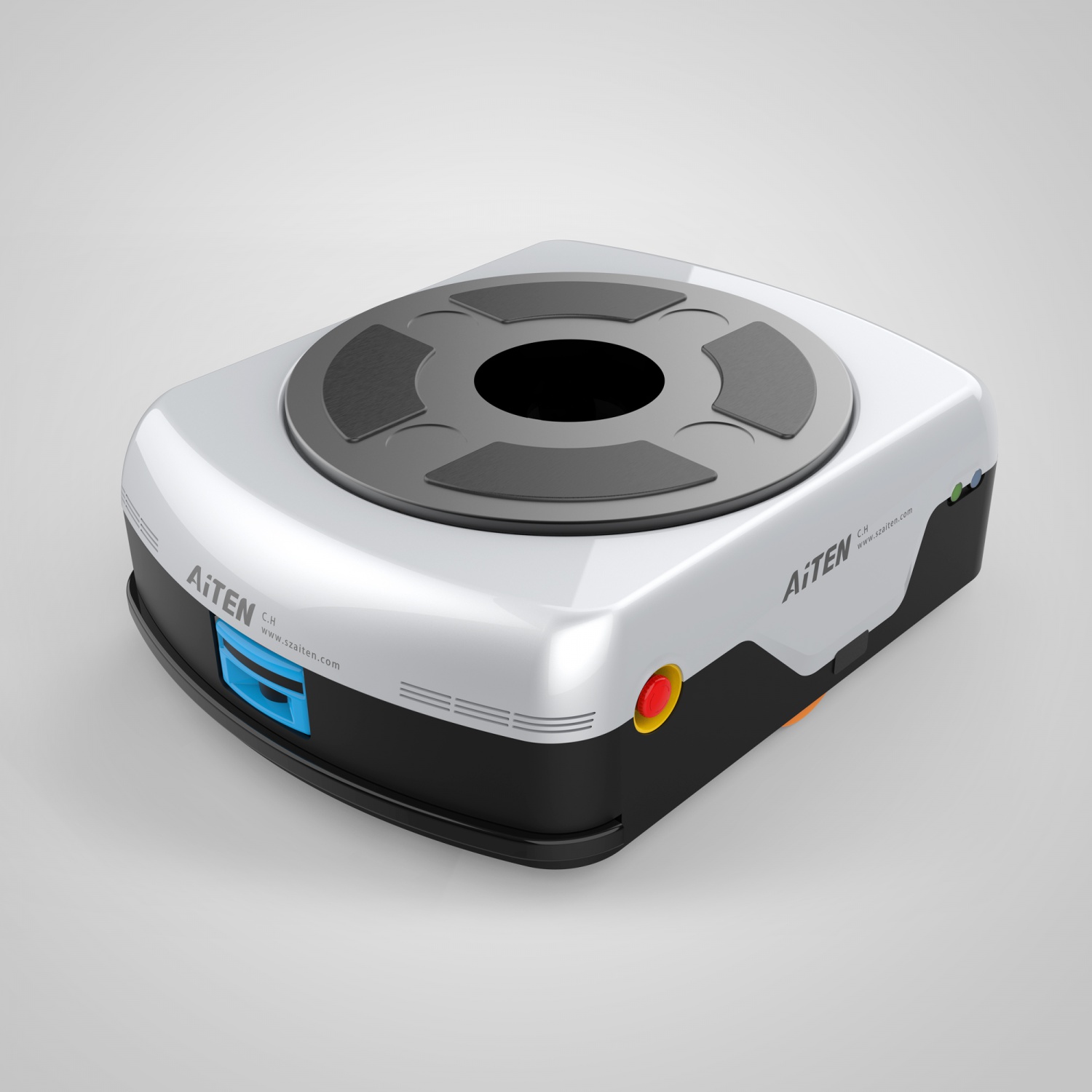

Drum type transporting and manipulating robot TD150

About the robot

| Robot name | Drum type transporting and manipulating robot TD150 | |||||

| Employment type | Full-time employees | |||||

| Dimensions |

| |||||

| Load capacity | 0.8\1.2 kg | |||||

| The speed of movement | ||||||

| Energy consumption | ||||||

| Working hours | ||||||

| The warranty period | ||||||

| Power |

Relocatable robot

*Payment terms, contracts, shipping/logistics, insurance details, etc. are provided upon request.

- Product Name TD150

- Main Features The navigation method is a laser HELMET / QR code

- Rated load (kg) 1500

- Weight (kg) 990

- Base size Length/width/Height (mm) 1620/1350/1000

- Minimum ground clearance (mm) 35

- Standard width of the protective channel (mm) 2220

- Basic performance Movement speed at full load /without load (m/s) 0.8/1.2

- Maximum lifting capacity at full load/ without load (%) 3/5

- On-site accuracy ±10

- Battery (V/Ah) 48/50

TD150 Heavy-Duty Robot Worker: Powerhouse Automation for Industrial Giants

Unmatched Load Capacity for Extreme Applications

The TD150 robot worker redefines heavy industrial automation with a staggering 1500 kg load capacity, making it the ultimate solution for businesses needing to hire robot power for mega-projects or invest in a robot for sale for permanent operations. With a movement speed of 0.8 m/s at full load (1.2 m/s unloaded), this industrial titan combines raw power with operational efficiency, perfect for the most demanding work for the robot in heavy manufacturing and logistics.

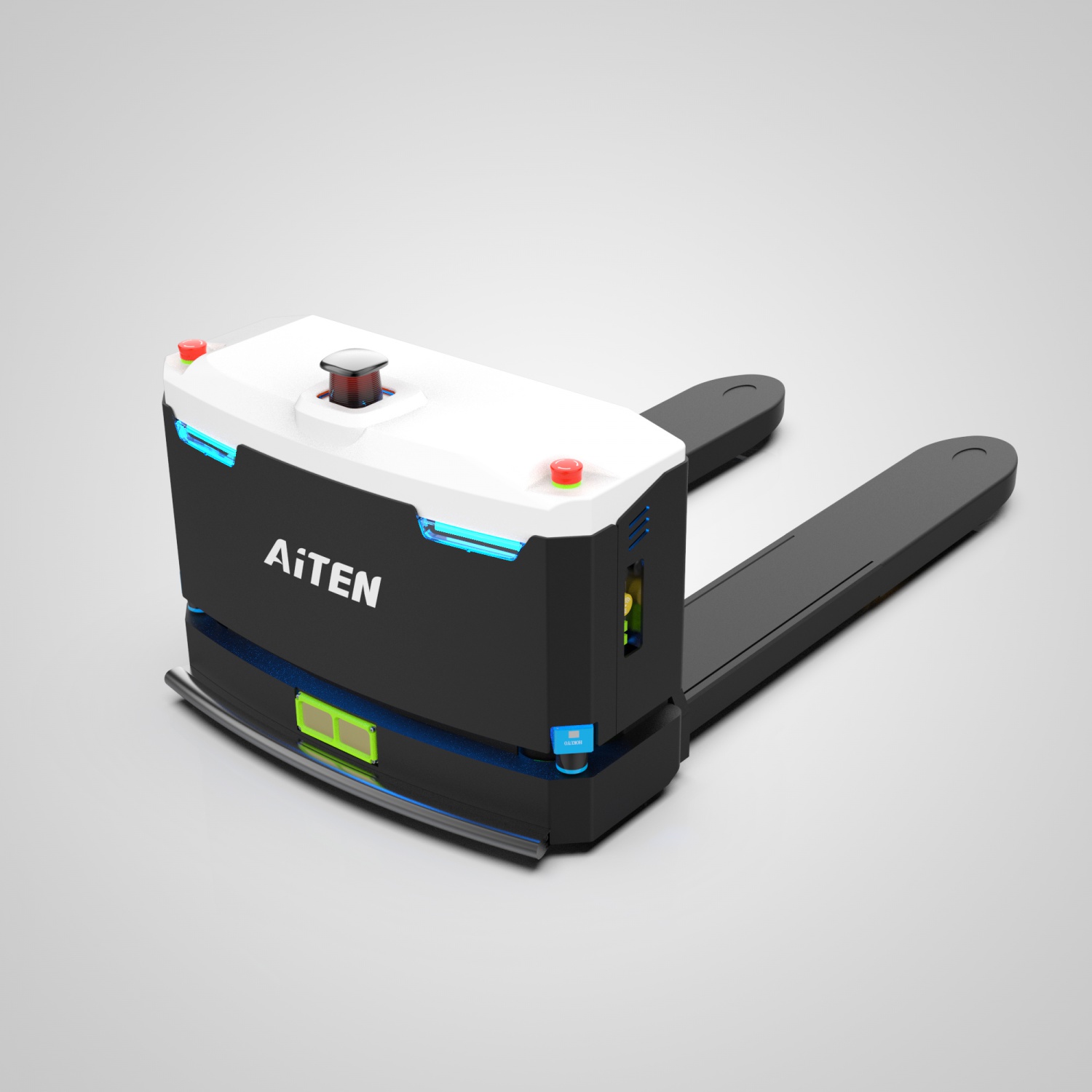

Precision Navigation in Challenging Environments

Equipped with advanced laser HELMET and QR code navigation systems, the TD150 maintains ±10 mm on-site accuracy even when handling massive loads. This precision makes it ideal for job for robots in steel mills, shipyards, and aerospace facilities where millimeter-perfect positioning is crucial. When you rent a robot with this level of technological sophistication, you gain a competitive edge in material handling precision.

Industrial-Grade Construction for Maximum Durability

Built around a robust 990 kg frame with dimensions of 1620/1350/1000 mm, this robot worker is engineered for the toughest industrial environments. The 35 mm ground clearance and expansive 2220 mm protective channel width ensure safe operation in facilities with uneven surfaces or limited maneuvering space. From foundries to heavy equipment warehouses, the TD150 thrives where conventional automation fails.

24/7 Performance for Non-Stop Operations

The TD150's impressive 3% lifting capacity at full load (5% unloaded) combined with its high-capacity 48V/50Ah battery enables continuous heavy-duty operation through extended shifts. This makes the robot for hire ideal for port container handling, mining operations, and large-scale construction projects where downtime isn't an option.

Transformative Applications Across Heavy Industries

Looking for where to deploy this robot worker? The TD150 excels in automotive plants moving complete vehicle chassis, at construction sites handling prefabricated structures, and in logistics hubs managing oversized cargo. Its combination of strength and precision opens new possibilities for automation in sectors previously reliant on manual labor or heavy machinery.

The Smart Investment in Industrial Automation

Whether you need to rent a robot for a specific project or purchase a robot for sale as a long-term automation solution, the TD150 delivers unmatched value. Its ability to handle extreme weights with precision reduces labor costs while improving workplace safety. The question isn't whether you can afford this robot worker, but whether you can afford to keep doing without it in today's competitive industrial landscape.

Future-Proof Your Operations Today

The TD150 represents the cutting edge of heavy-load automation technology. From power plants to heavy machinery manufacturing, this robot for hire is ready to take on your most challenging material handling tasks. Discover how integrating the TD150 into your operations can revolutionize your productivity and bottom line - because in heavy industry, the strongest competitors will be those who automate smartest.

Robots from the manufacturer

Robot for industry

- Articulated

- Autonomous

- Mobile

- (AMRs)

- Industrial