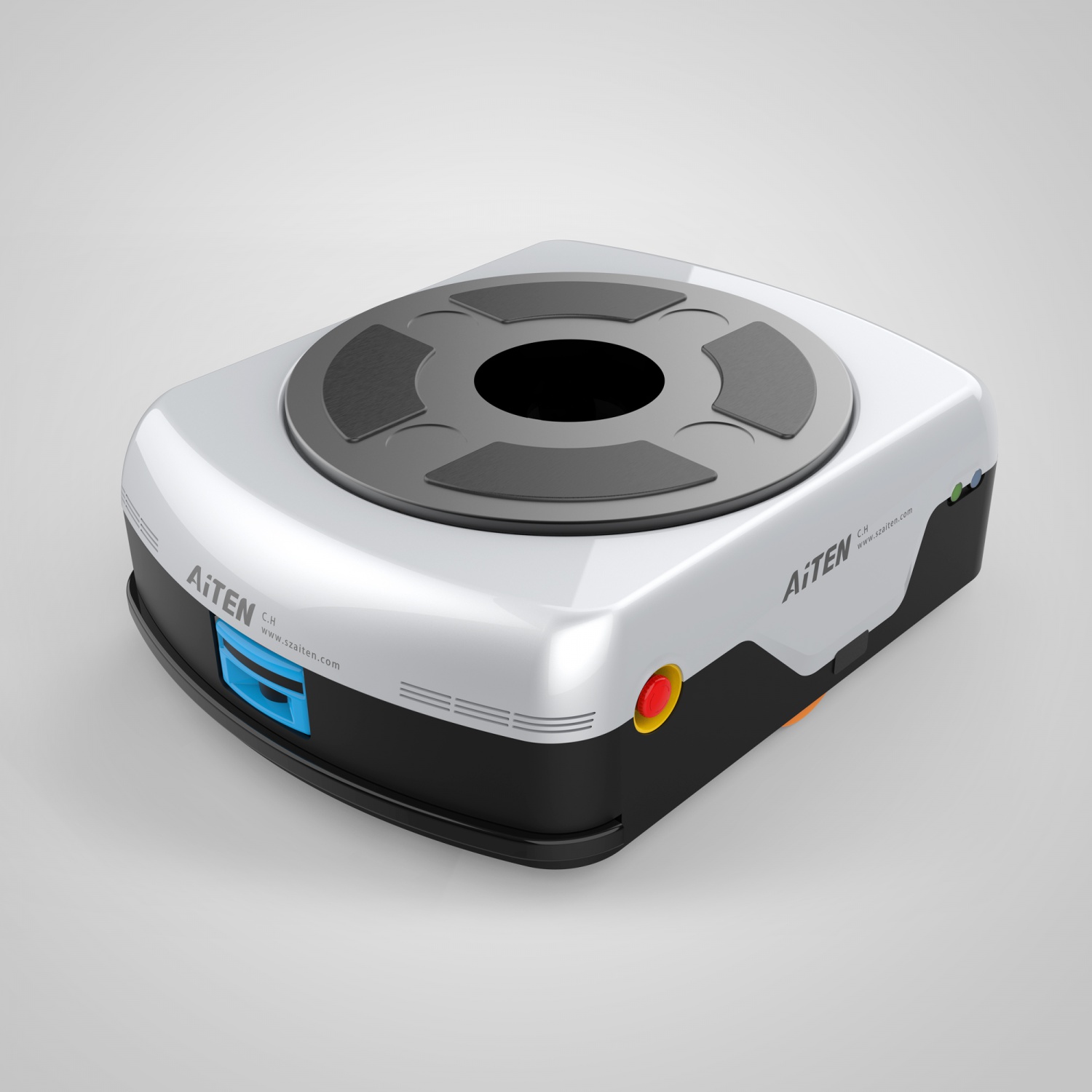

ML03 AGF handling robot

About the robot

| Robot name | ML03 AGF handling robot | |||||

| Employment type | Full-time employees | |||||

| Dimensions |

| |||||

| Load capacity | 300 kg | |||||

| The speed of movement | 0.8-1.2 kg | |||||

| Energy consumption | ||||||

| Working hours | 6-8 kg | |||||

| The warranty period | ||||||

| Power |

Relocatable robot

*Payment terms, contracts, shipping/logistics, insurance details, etc. are provided upon request.

Basic Features:

- Drive Form: Steering wheel

- Navigation Method: LASER SLAM

- Rated Load: 300 kg

- Load Center: 300 mm

- Weight: 140 kg

- Tire Type: Polyurethane wheel

- Braking Method: Electromagnetic braking

- Communication: Wi-Fi/5G

- Charging Method: Manual/Automatic

Basic Size:

- Dimensions (L×W×H): 920 × 400 × 1365 mm

- Lifting Height: 200 mm

- Min. Cargo Height from Ground: 100 mm

- Fork Size: 70/210/600 mm

- Outer Width of Goods: 210 mm

- Right-Angle Stacking Width (1000×1200 pallet): 1000 mm (fork: 1200 mm)

- Min. Ground Clearance: 20 mm

- Turning Radius: 690 mm

Basic Performance:

- Driving Speed:

- Full Load: 0.8 m/s

- No Load: 1.2 m/s

- Lifting/Descending Speed: 25 mm/s (both full/no load)

- Max. Climbing Ability:

- Full Load: 3°

- No Load: 5°

- Positioning Accuracy: ±10 mm

- Battery: 48V/25Ah

- Operating Time: 6–8 hours

- Full Charge Time: ≤1.3 hours

Safety Features:

- Laser Obstacle Avoidance

- Mechanical Anti-Collision

- Sound & Light Alarm

- Emergency Stop Button

- Charge/Discharge Protection

- Fork Tip Detection

- Goods Placement Inspection

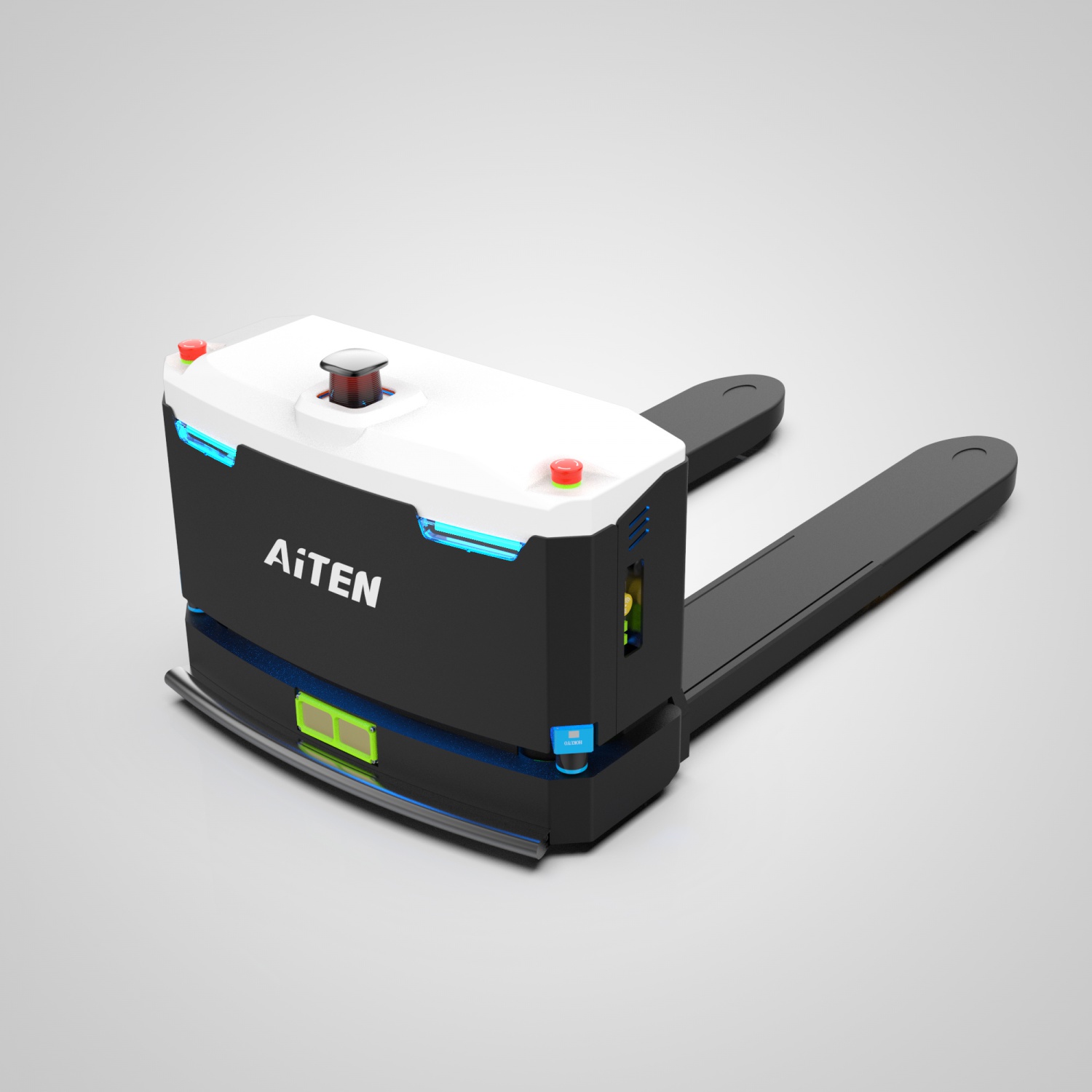

ML03 Autonomous Mobile Robot – Smart Narrow-Aisle Material Handling Solution

Revolutionizing Logistics with Compact Automation

The ML03 represents the next generation of autonomous robots designed specifically for narrow-aisle material handling. As a versatile logistics robot, it combines advanced AI in robotics with space-efficient design to transform warehouse operations and production line workflows. With a 300kg payload capacity, 200mm lifting height, and compact 690mm turning radius, this smart robot delivers exceptional performance in confined spaces where traditional equipment cannot operate.

Intelligent Navigation for Complex Environments

Utilizing cutting-edge SLAM and laser navigation technology, the ML03 autonomous robot scans and maps its surroundings in real-time, automatically calculating optimal routes through dynamic environments. The system's comprehensive obstacle avoidance capabilities, powered by multiple sensors, ensure safe operation alongside human workers. Whether you need to hire robot solutions temporarily or invest in robots for sale for permanent deployment, this logistics automation system adapts to your specific material handling requirements.

Space-Optimized Design for Modern Facilities

The ML03's compact dimensions (920×400×1365mm) make it ideal for warehouse robotics applications where space is at a premium. Its narrow profile allows effortless navigation through tight aisles and congested work areas, solving the challenges of material distribution in production workshops and automated warehouse environments. The robotic process automation capabilities enable seamless integration with existing workflows while maintaining maximum operational flexibility.

Transformative Benefits for Your Business

Implementing the ML03 robot worker delivers measurable improvements across your operations. The system enables 24/7 automated material transport, significantly reducing labor costs and human error in repetitive handling tasks. Advanced energy management systems optimize power consumption, while precision navigation ensures accurate placement of goods, minimizing product damage. Companies adopting this AI in robotics solution not only boost efficiency but also enhance their corporate image as leaders in technological innovation.

Versatile Applications Across Industries

This smart robot excels in numerous material handling scenarios: automated warehouse operations where it moves goods between storage and picking areas, production line feeding systems that require just-in-time delivery of components, pharmaceutical facilities needing precise material transport, and retail distribution centers managing high-volume inventory. The ML03's ability to handle various load types makes it equally effective for raw material transport in manufacturing plants and finished goods movement in fulfillment centers.

Proven Technology Ready for Deployment

The ML03 autonomous robots incorporate multiple safety features including laser obstacle detection, mechanical anti-collision systems, and emergency stop functions, ensuring reliable operation in busy industrial environments. With options to rent a robot for temporary needs or purchase for permanent installation, businesses of all sizes can access this advanced logistics automation technology.

Take the Next Step Toward Automation

Our team of experts is available to demonstrate how the ML03's AI-powered capabilities can be tailored to your specific operational requirements, whether you're looking to implement robots in logistics for the first time or expand your existing fleet of warehouse robotics.

Upgrade to Smarter Material Handling – Contact Us Today

Robots from the manufacturer

Robot for industry

- Automated

- Guided

- Vehicles

- (AGVs)

- Logistics

- Warehouse

- Robotics