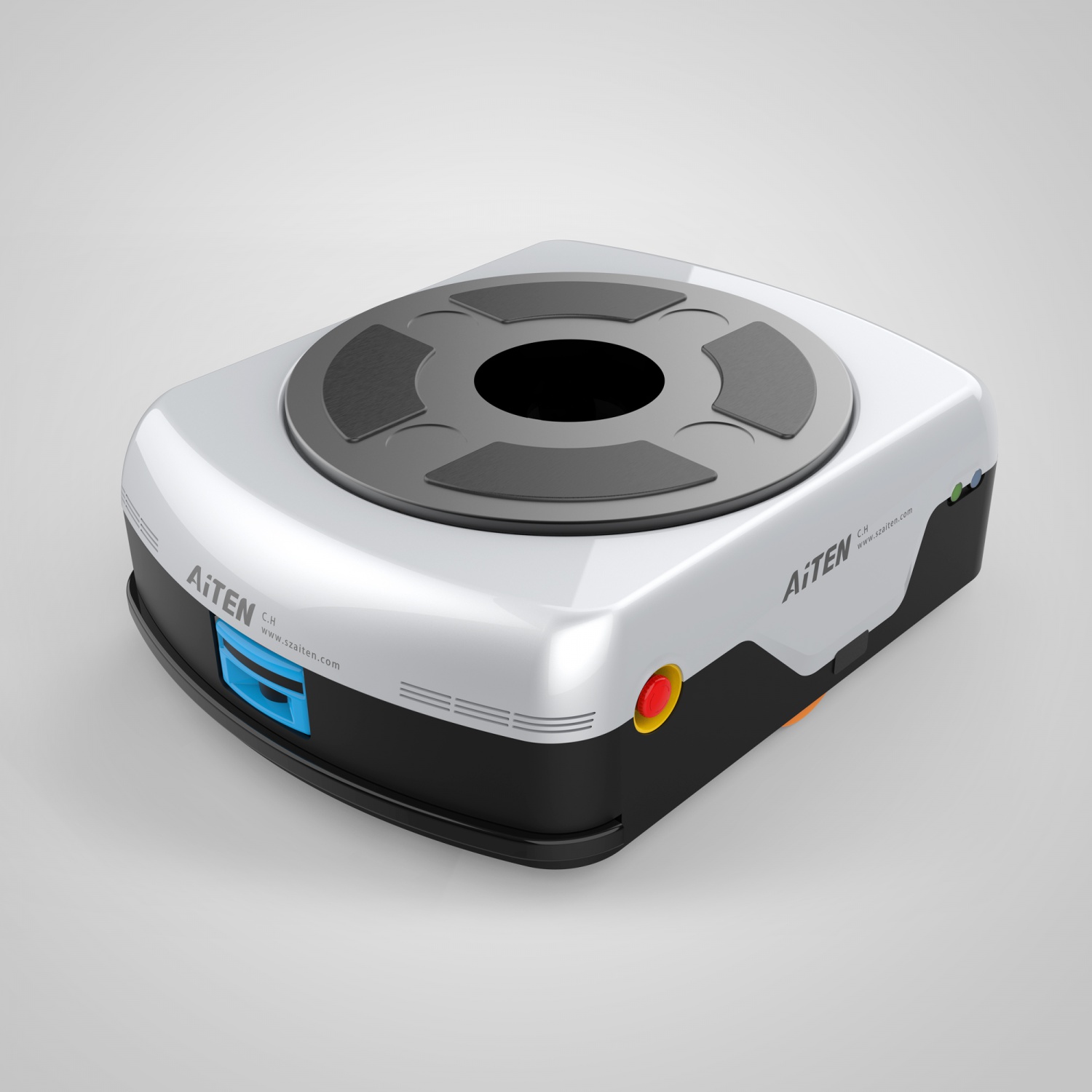

AS15 handling robot

About the robot

| Robot name | AS15 handling robot | |||||

| Employment type | Full-time employees | |||||

| Dimensions |

| |||||

| Load capacity | 1500 kg | |||||

| The speed of movement | 1.5-2 kg | |||||

| Energy consumption | ||||||

| Working hours | ||||||

| The warranty period | ||||||

| Power |

Relocatable robot

*Payment terms, contracts, shipping/logistics, insurance details, etc. are provided upon request.

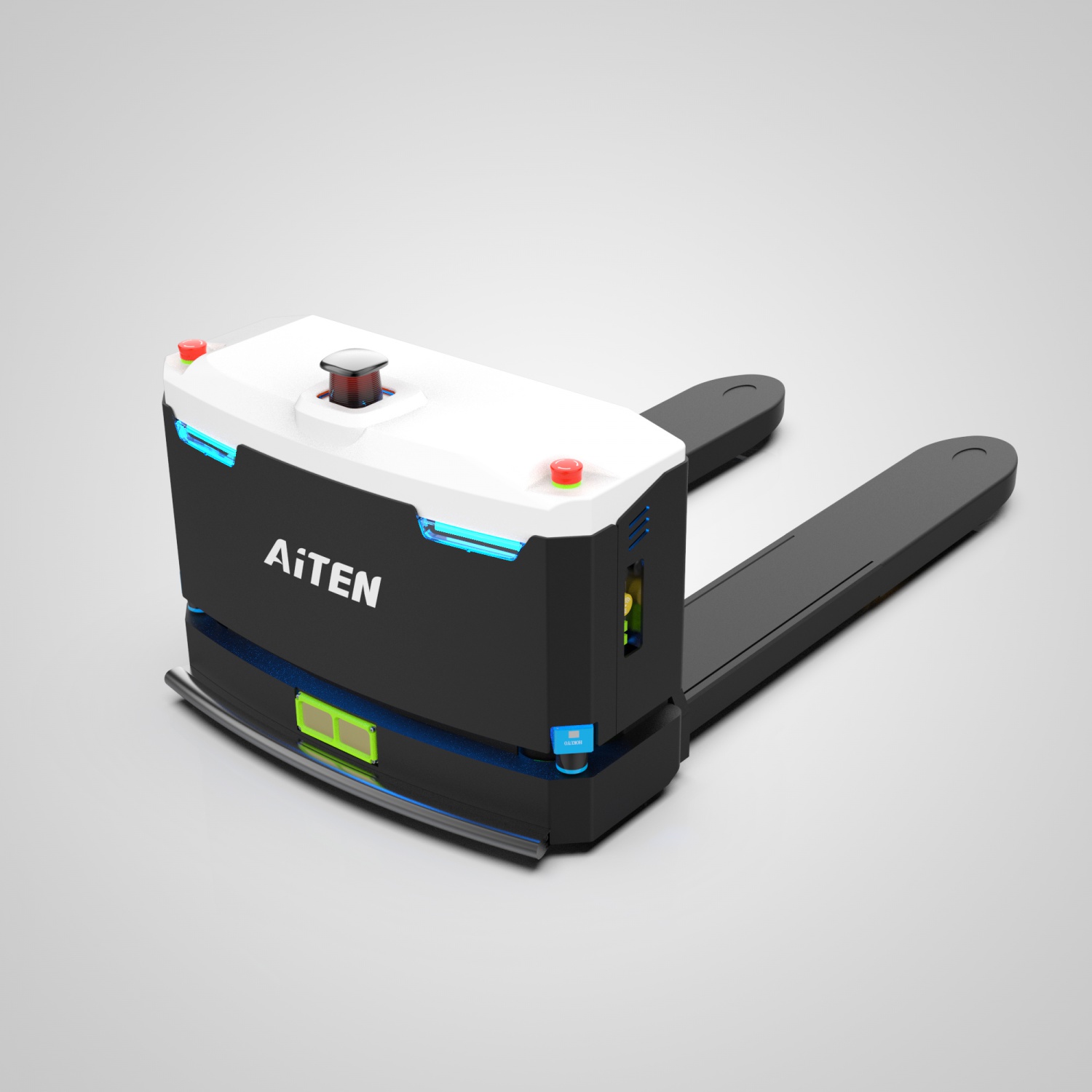

- Rated Load Capacity: 1500 kg

- Load Center: 600 mm

- Robot Weight: 995 kg

Dimensions

- Length/Width/Height: 1902 × 890 × 2020 mm

- Lifting Height: 3000 mm (standard)

- Fork Height (Lowest Position): 87 mm

- Right-Angle Stacking Width (1000×1200 pallets): 2350 mm

- Turning Radius: 1430 mm

Performance

- Driving Speed:

- Full Load: 1.5 m/s

- No Load: 2 m/s

- Battery: 24V/210Ah

- Optional Lifting Heights

- Single-Stage Mast: 0-1600 mm

- Two-Stage Mast: 0-6000 mm

- Three-Stage Mast: 0-7000 mm

AS15 Heavy-Duty Autonomous Forklift – The Future of Industrial Material Handling

Next-Generation Power for Smart Warehousing

Meet the AS15 – a game-changing autonomous robot that's transforming heavy-load operations with its remarkable 1500kg capacity and 3000mm vertical reach. This intelligent logistics robot combines industrial strength with cutting-edge AI in robotics to revolutionize how businesses handle their most challenging material movement tasks. Its compact 1430mm turning circle delivers unparalleled agility for a machine of this capability, proving that in warehouse robotics, power and precision can coexist perfectly.

Engineered for Non-Stop Productivity

The AS15 smart robot features industry-leading battery technology that keeps operations running longer while minimizing charging downtime. As a versatile robot worker, it effortlessly adapts to various load types through its modular design – from standard pallets to specialized containers. Whether you're looking to rent a robot for seasonal peaks or purchase robots for sale as a long-term solution, this autonomous workhorse delivers consistent, reliable performance across multiple shifts.

Intelligent Movement with Surgical Precision

Advanced robotic process automation gives the AS15 millimeter-perfect positioning accuracy at every transfer point. Its sophisticated navigation system, powered by AI robots technology, creates real-time environmental maps while intelligent sensors maintain flawless obstacle avoidance. This logistics automation marvel doesn't just move materials – it calculates, adapts, and optimizes every movement for maximum efficiency.

The Brain Behind Your Automated Workforce

The AS15's intelligent dispatching system represents the pinnacle of multi-robot collaboration in warehouse robotics. Through seamless robotic process automation, fleets of these autonomous robots communicate and coordinate like a well-rehearsed team, dynamically adjusting paths and priorities to keep your operations flowing smoothly. From production line feeding to cross-facility transfers, this smart logistics solution handles complex material flows with ease.

Measurable Impact on Your Bottom Line

Deploying AS15 robot workers generates transformative operational benefits: significant labor cost reductions, near-elimination of handling errors, and dramatically improved workplace safety through its optimized stability systems. With seamless WMS/ERP integration, this AI in robotics solution becomes the intelligent backbone of your digital transformation, providing data-driven insights alongside physical automation.

Built for the Toughest Industrial Challenges

The AS15 autonomous robot thrives in demanding environments: automotive plants requiring precise production line distribution, cold storage facilities needing reliable freezer operations, construction material yards handling heavy loads, and distribution centers managing high-bay storage. Its ability to automate cargo stacking and high-level access makes it invaluable for modern logistics automation across sectors.

Industrial-Strength Safety You Can Trust

Every AS15 combines rugged construction with intelligent safety systems – industrial-grade components, redundant stability controls, and real-time load monitoring ensure secure operation even at maximum capacity and height. This isn't just warehouse robotics; it's engineered reliability that protects both your materials and your team.

Experience the AS15 Difference

Discover how this robotic process automation solution can transform your operations. Our automation consultants are ready to tailor a solution matching your exact material handling requirements.

Robots from the manufacturer

Robot for industry

- Automated

- Guided

- Vehicles

- (AGVs)

- Logistics

- Warehouse

- Robotics