Robotics companies Realtime Robotics and Germany's HLS Engineering Group are joining forces to optimize robot automation for manufacturers seeking quick productivity gains. By combining Realtime's motion planning software with HLS's systems integration prowess, they aim to slash deployment times from months to weeks.

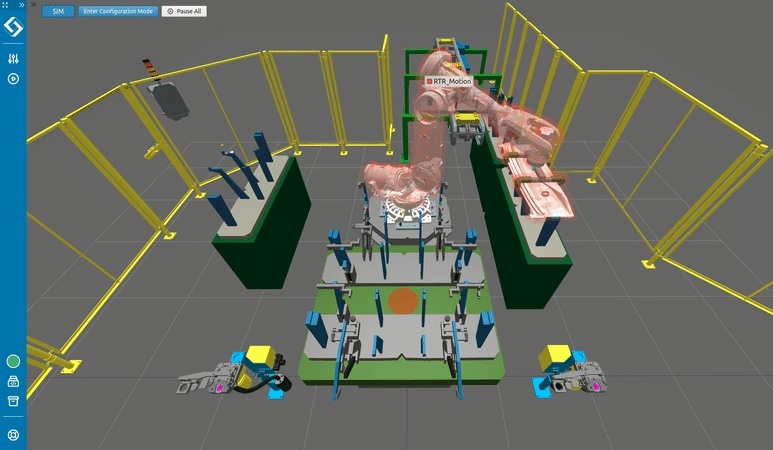

Realtime's technology generates ultra-efficient motion sequencing for robots working in close proximity. This allows smoother coordination, collision avoidance and minimized cycle times across multi-arm workcells. Their new joint Optimization-as-a-Service offering promises rapid existing line improvements.

HLS will create digital twin models of production environments using advanced scanning techniques. Realtime then leverages this virtual representation to simulate thousands of optimized robot motions considering reach, workplace layouts and target process speed-up opportunities identified by manufacturers.

Rather than costly offline testing, the partnership validates enhancements in simulation then initiates upgrades seamlessly alongside active production. The companies suggest typical processes like CNC machine tending could see drastic lead time and precision boosts without traditional integration pains.

"Our combined expertise and tech helps manufacturers find additional efficiency without forcing manual testing," explained Realtime CEO Peter Howard. "Targeted analysis surfaces unrealized potential in current robot assets."

Serving automotive firms for over 55 years, HLS brings both industry experience and technical implementation capabilities to wring out latent robot performance. Their integration proficiency and digital replication abilities combined with Realtime's analytics unlocks turnkey refinement.

As off-the-shelf automation confronts adaptability hurdles, this union presents welcome flexibility without forfeiting production continuity. Their cooperative solution looks to propel manufacturers toward their ideal automated environment in months rather than years.