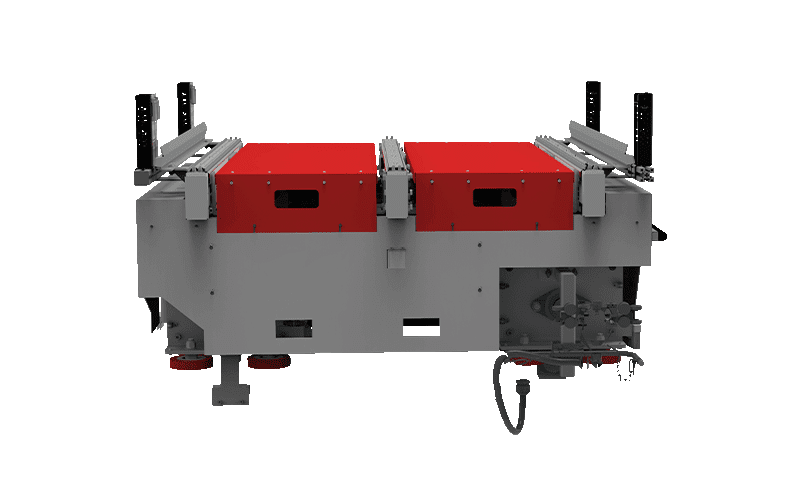

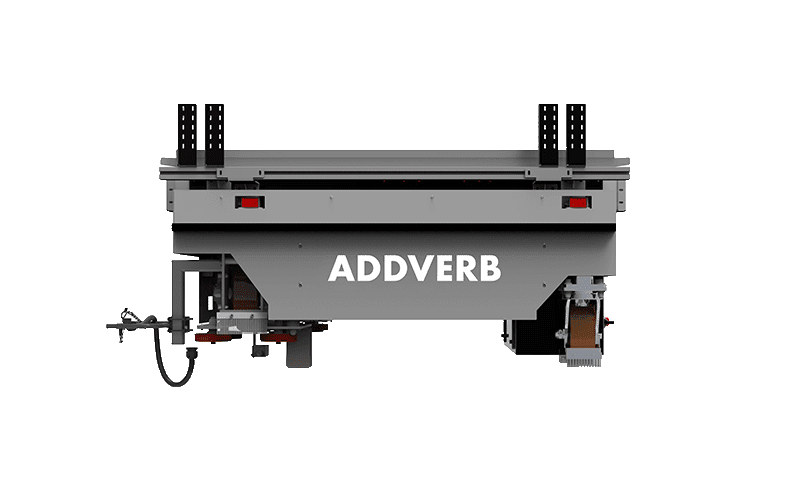

Travect

About the robot

| Robot name | Travect | |||

| Employment type | Full-time employees | |||

| Dimensions |

| |||

| Load capacity | ||||

| The speed of movement | ||||

| Energy consumption | ||||

| Working hours | ||||

| The warranty period | ||||

| Power |

Relocatable robot

*Payment terms, contracts, shipping/logistics, insurance details, etc. are provided upon request.

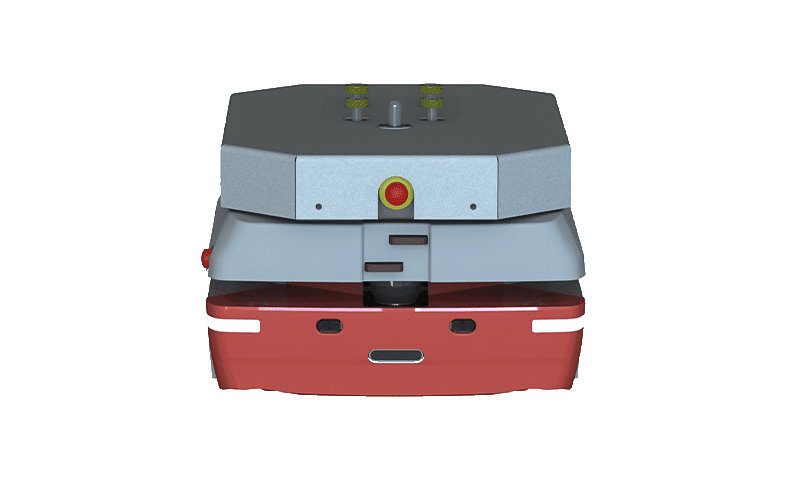

Rail-guided vehicles (RGVs) in a warehouse can offer several advantages in terms of efficiency, productivity, and safety. Here are some of the optimal use-cases:

Travect can be used to transport materials, goods, or pallets within the warehouse. They can follow predefined routes on the rails, enabling efficient movement without the need for human intervention.

Travect equipped with picking arms or shelves can navigate through the warehouse, locate specific items or orders, and pick them up for further processing or shipping. This streamlines the order fulfilment process and reduces manual labour.

Equipped with sorting mechanisms, Travect can efficiently sort and divert items based on predefined criteria, such as destination, order priority, or product type. This enables faster processing and dispatching of goods to their respective locations.

Increased Efficiency: RGVs follow optimized routes, minimizing travel time and maximizing productivity.

Enhanced Safety: Rail guidance ensures stability and reduces the risk of collisions, creating a safer work environment.

Flexibility and Scalability: The rail network can be easily modified to accommodate changing warehouse layouts and operational needs.

Cost Reduction: RGVs automate material handling, reducing labour costs, optimizing space utilization, and improving overall efficiency.

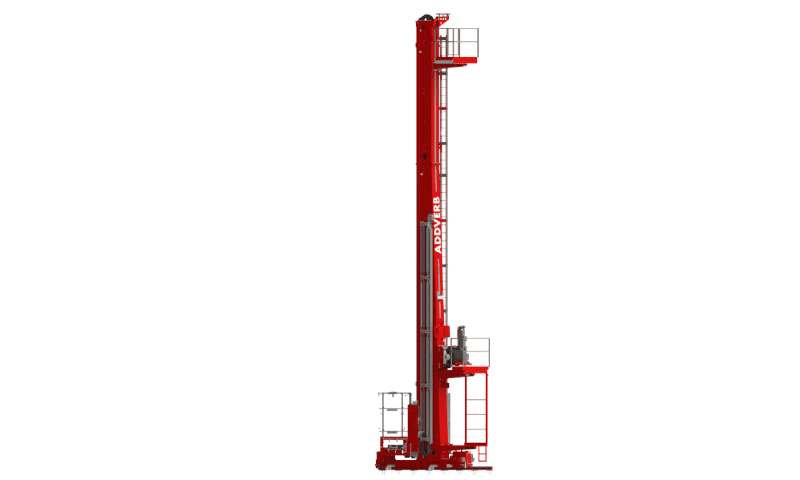

Robots from the manufacturer

Robot for industry

- Automated

- Guided

- Vehicles

- (AGVs)