Universal Robots hosted an open house event to showcase how its collaborative robots are ready for wide-scale adoption across industrial applications. With over 400 attendees, the event highlighted cobot palletizing, machine tending, surface finishing and more through partner demos.

Once considered not robust enough, improvements in payload, precision and ease-of-use now enable cobots to take on demanding tasks like loading pallets and CNC tending. Partners like Robotiq, Flexxbotics and New Scale Robotics exhibited customized solutions made possible by UR's flexible platforms and growing ecosystem.

For small and midsize manufacturers lacking automation expertise, cobot solutions make automation accessible. Intuitive programming, plug-and-play peripherals and intrinsic safety mitigate common barriers to adoption. Versatility enables a single cobot to switch between multiple processes.

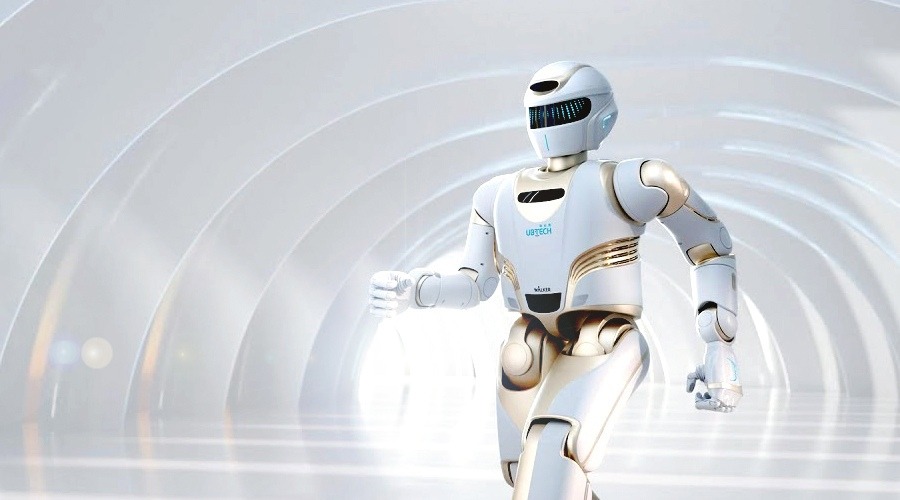

With expanded capabilities and simplified deployment, UR envisions collaborative robots augmenting human workers across the shop floor. MIT's Julie Shah explained how "positive-sum automation" can enhance productivity and jobs, versus notions of robots "stealing" roles.

Tests by partners suggest combining UR cobots with the right grippers, software and sensors unlocks new potential. This also expands UR's ecosystem, where customers can source complete solutions.

As advanced functionality enables more applications, UR aims to show manufacturers that collaborative robotics is no longer an experiment but a turnkey path to accuracy, quality and safety. With the power of automation more distributed and accessible than ever, UR helps even small facilities leap into competitively manufacturing the future.