ABB has successfully tested an industry-first robotic charging system for underground mining called Robot Charger, developed jointly with Swedish companies Boliden and LKAB. The automated solution can load explosives into blast holes, removing workers from hazardous areas during blasting operations.

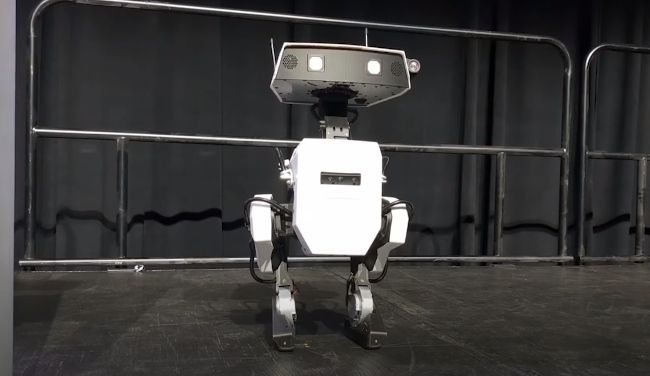

Robot Charger is designed to make mines safer by eliminating one of the last manual processes in modern mining. The robot can be installed on any truck and autonomously detects and charges blast holes with emulsion explosives without human involvement.

Testing was conducted at Boliden's Garpenberg zinc mine, where blasting occurs up to 15 times daily. The trials validated Robot Charger's integration with vehicles, vision-based hole identification, explosive delivery system, and remote control operation. Dual robotic arms allow automatic fuse and detonator assembly while achieving full coverage of the blast hole.

By keeping workers away from unstable rock faces during charging, Robot Charger aims to prevent serious injuries and deaths. The system also increases charging consistency and efficiency compared to manual work.

ABB will now work towards completing an entire automated charging cycle underground. The company is in talks with other mining firms about further testing Robot Charger across diverse conditions and geographies beyond Northern Europe.

"The goal is to make mines safer by automating one of the last manual processes in the industry," said ABB's Mining division president Max Luedtke. "In successfully completing testing, we have validated the safety benefits and potential of Robot Charger."

The robot marks a major step towards fully-automated underground mining. Combined with other autonomous technologies like driverless haul trucks, it builds on ABB and partners' prior R&D investments to remove workers from the most hazardous tasks. By embracing automation, forward-looking mining companies can boost safety and productivity.