Imagine a robot that can build a three-story house by squeezing out concrete like toothpaste from a tube. That's exactly what a California company called RIC Technology has created with their newest construction robot, and it's pushing the boundaries of what automated building machines can do.

The company just unveiled their latest creation, called RIC-PRIMUS, which towers over its predecessor like a big brother. This new robot can print buildings up to 32 feet high – about three stories – making it nearly twice as tall as the previous model. To put that in perspective, it's like going from being able to print a standard house to being able to print a small apartment building.

The robot is already catching the attention of major companies. Walmart, for instance, recently had RIC's previous robot build an 8,000-square-foot extension to one of their stores. The retail giant was so impressed that they're planning 200 more similar projects starting in February 2025.

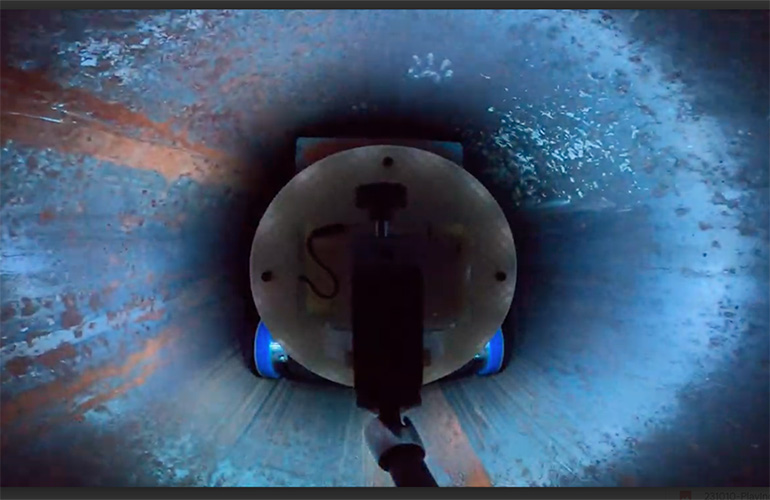

But what makes these building robots special isn't just their size – it's how they work. Think of them as oversized 3D printers that use concrete instead of plastic. The RIC-PRIMUS can zip along at nearly 8 inches per second, printing walls with precise patterns. It's smart enough to print around obstacles like metal reinforcement bars and can even print up against existing buildings.

One of the most impressive features is how quickly these massive machines can get to work. Despite their size, they can be ready to start building within two to four hours of arriving at a construction site. This is a huge improvement over traditional construction robots that could take days just to set up.

The robot is also helping to address a growing challenge in the construction industry: the shortage of skilled workers. While traditional construction methods might require large crews, the RIC-PRIMUS needs only two operators to keep it running. It even comes with a system that checks the quality of the concrete in real-time, helping to prevent mistakes and ensure buildings are safe and sturdy.

"This is a huge step forward for building things in a new way," says Ziyou Xu, who founded RIC Technology and created their robot construction program. The company believes their robots could help build houses and commercial buildings faster and more cheaply than traditional methods.

For those curious to see these building robots in action, RIC Technology will be showing off their machines at the World of Concrete event in Las Vegas this January. They'll be working with several partners, including a cement workers' union, to demonstrate how the robot prints structural walls.

The development of these increasingly capable construction robots points to a future where building homes and commercial structures might look very different from today. As these machines get taller, faster, and smarter, they could help address housing shortages by making construction quicker and more affordable.

While we're still a long way from robots completely taking over construction sites, machines like the RIC-PRIMUS are showing that automation can play a bigger role in how we build our world. As construction companies face ongoing challenges with labor shortages and rising costs, these high-tech helpers might become an increasingly common sight at building sites across the country.