Collaborative Robotics has unveiled its latest innovation in the automation space – a mobile robot worker called Proxie that could reshape how we think about warehouse automation. The Santa Clara-based company's reveal comes as the industry debates the practicality of humanoid robots in industrial settings.

Brad Porter, the company's founder and former Amazon robotics executive who led the deployment of over 500,000 robots, is taking a distinctly different approach from the current trend toward humanoid robots. "Mobile manipulators are a better solution than humanoids," Porter asserts, citing his extensive experience in warehouse automation at Amazon. His critique of humanoid robots centers on their practical limitations: despite their eye-catching design, they lack the necessary strength for many warehouse tasks, such as moving heavy carts weighing up to 1,500 pounds – a task Proxie can handle with ease.

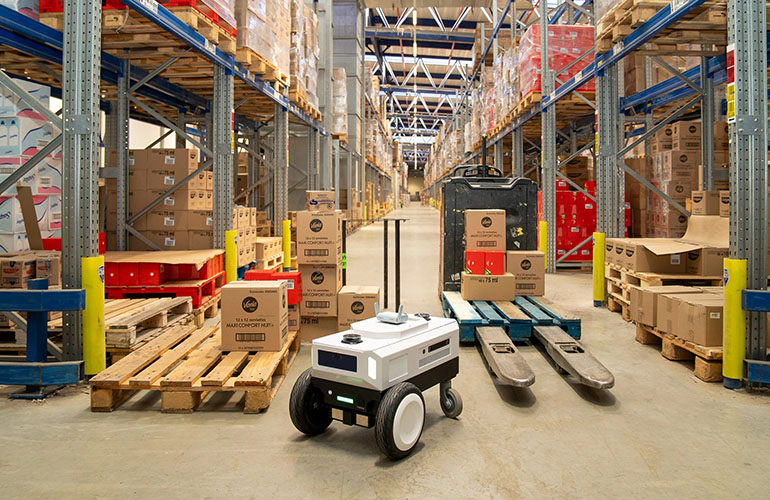

The robot's design prioritizes functionality over human mimicry. Its base features four "swerve drive" motors enabling holonomic motion, allowing the robot worker to move smoothly in any direction, including sliding sideways into shelving units. This capability gives Proxie significant advantages over traditional differential drive systems in navigating tight warehouse spaces.

Already in trials with several pilot customers, including a global logistics company, Proxie has attracted attention from notable organizations such as Moderna, Mayo Clinic, and Tampa General Hospital. While maintaining roughly human stature, the robot incorporates a vertical linear axis supporting a dual arm cart interfacing gripper, with plans to offer an optional six-degree-of-freedom collaborative robot arm in future configurations.

The timing of Proxie's debut coincides with growing industry interest in mobile manipulation robots. Mobile Industrial Robots (MiR) has also introduced their MC600 model, suggesting a broader industry shift toward practical, task-specific robotic solutions rather than humanoid designs.

As these robot workers continue to evolve, industry standards are keeping pace. ASTM International's F45 committee is developing new standards to evaluate mobile manipulators' performance in unstructured environments, particularly their response to real-world disturbances – a crucial consideration for industries ranging from manufacturing to healthcare.

With a recent $100 million Series B funding round and a new Seattle office focused on AI development, Collaborative Robotics appears well-positioned to advance its vision of practical warehouse automation that prioritizes capability over anthropomorphic design.