Figure, a pioneering robotics company, has released new footage showcasing the remarkable progress of its humanoid robot as it prepares for its groundbreaking role at a BMW manufacturing plant. This latest development marks a significant milestone in the integration of advanced AI-powered robots into real-world industrial settings.

The sleek, silver humanoid, known as Figure 01, has been undergoing intensive training to master complex tasks essential for automotive manufacturing. The recently released video demonstrates the robot's growing capabilities in handling intricate car parts with precision and care.

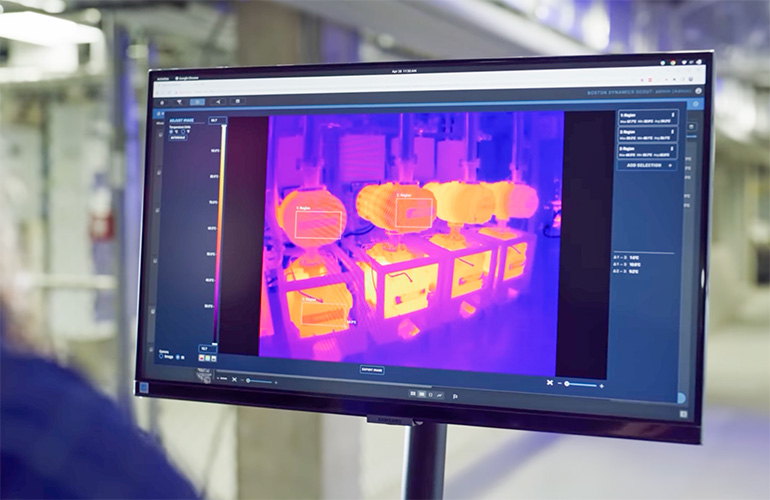

Key highlights from the demonstration include:

- Advanced Grasping: Figure 01 showcases its ability to manipulate large, complex shapes using its rubber-tipped fingers, demonstrating a level of dexterity crucial for automotive assembly.

- Spatial Awareness: The robot navigates its workspace efficiently, avoiding collisions while transporting components – a critical skill in busy manufacturing environments.

- Precision Placement: Figure 01 successfully places a large plate onto a jig, navigating around obstructed locating pegs – a task requiring both strength and finesse.

- Problem-Solving: The robot demonstrates adaptive behavior by correctly orienting misaligned parts and using gentle taps to ensure proper seating of components.

- Quality Control: Figure 01 shows the ability to recognize and correct its own errors, a key feature for maintaining high production standards.

While the robot's movements are currently deliberate and measured, Figure emphasizes that speed and fluidity will improve as the AI continues to learn and evolve. This methodical approach underscores the company's commitment to safety and reliability in industrial settings.

Figure's founder, Brett Adcock, highlights the strategic importance of partnering with external customers like BMW: "Having an external customer, which will fire us if we fail, will be a competitive advantage for Figure." This philosophy drives the company to meet real-world demands and standards, pushing the boundaries of what's possible in robotics.

As Figure 01 prepares for its debut on the BMW production floor, it represents a significant step forward in the integration of AI-powered humanoid robots into mainstream manufacturing. This collaboration between Figure and BMW not only showcases the potential of next-generation robotics but also signals a new era in human-robot cooperation in industrial environments.

The ongoing development of Figure 01 promises to yield valuable insights into the practical applications of humanoid robots, potentially revolutionizing workforce dynamics and production efficiency in the automotive industry and beyond.