Transforming Workplace Safety: The Power of Comau MATE-XT Exoskeletons

John Deere employees now have access to cutting-edge Comau MATE-XT exoskeletons, marking a significant leap forward in workplace safety and efficiency. These innovative devices are engineered to sustain worker well-being, alleviate physical stress, and mitigate ergonomic risks within the intricate parts logistics operations of John Deere.

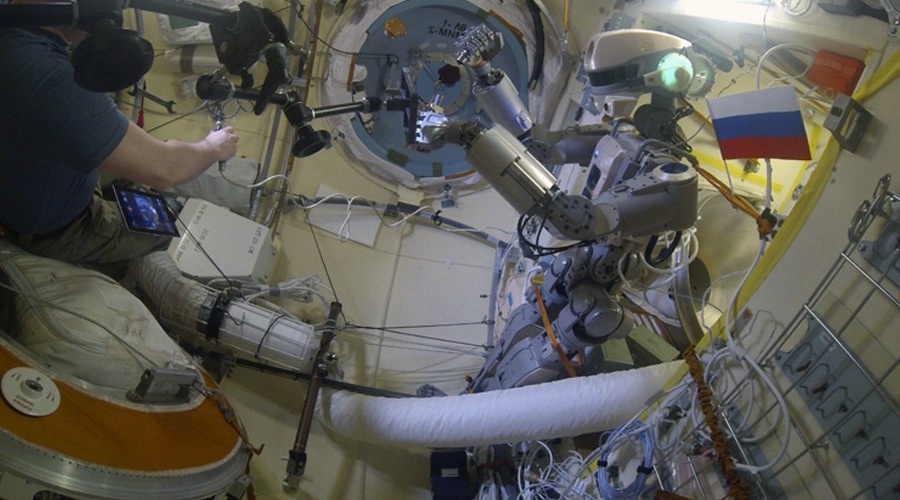

The MATE-XT exoskeleton, designed to be worn like a backpack, revolutionizes the way employees interact with their work environment. By accurately replicating all shoulder movements, this ergonomic marvel enables employees to perform their tasks comfortably, effectively reducing muscle fatigue without compromising mobility or adding unnecessary bulk. For John Deere employees, this means enhanced productivity as they seamlessly handle hundreds of packages daily, ensuring that critical parts are readily available for next-day delivery.

Comau’s MATE-XT exoskeleton stands out for its economic design and adaptability to diverse body types. With easily adjustable shoulder straps and customizable assistance levels, tailored support is provided based on individual worker requirements or specific job demands. The exoskeleton's Ergonomic Assessment Work-Sheet (EAWS) certification underscores its efficacy, offering tangible measurements of ergonomic improvements and projected benefits such as reduced muscle fatigue and enhanced execution speeds.

Practical training sessions conducted by Comau at John Deere's expansive parts distribution center in Campinas, São Paulo, Brazil, have equipped employees with the necessary skills to leverage these innovative devices effectively. Laerte Scarpitta, Comau Leader for the Americas, emphasizes the company's commitment to ensuring worker safety across various applications and markets. The MATE-XT exoskeleton exemplifies this dedication by providing measurable benefits, including reduced muscle fatigue and minimized mechanical stress on critical areas such as the back, lumbar region, arms, and shoulders.

Quantifying the advantages of the MATE-XT exoskeleton, Comau conducted electromyographic analyses to evaluate ergonomic risks with and without the device. Results revealed a remarkable improvement, with the exoskeleton keeping muscles at a resting stage for 98.5% of the activity time, compared to a mere 2.4% without it. Furthermore, MATE-XT promotes muscular balance and optimizes energy expenditure, enabling arm stability using only 10% of the operator’s maximum capacity while wearing the exoskeleton.

Headquartered in Turin, Italy, Comau has been at the forefront of robotics innovation since its establishment in 1973. The recent announcement of the development of a mobile manipulator for three different EU projects underscores the company's continuous pursuit of groundbreaking solutions. Comau's Mobile Robotic Arm, featuring a robotic arm mounted on an autonomous mobile platform, exemplifies its commitment to advancing automation technologies.

In conclusion, Comau MATE-XT exoskeletons represent a paradigm shift in workplace safety, empowering employees to work efficiently while minimizing physical strain and ergonomic risks. By leveraging cutting-edge robotics technology, John Deere reinforces its commitment to employee welfare and operational excellence, setting new standards for safety and productivity in the parts logistics industry.