Interroll, a global conveyor system leader, partnered with Mobile Industrial Robots (MiR) to create a conveyor module for MiR's autonomous mobile robots (AMRs). This combines Interroll's conveyor expertise with MiR's AMR technology to streamline internal logistics.

The module is certified for MiR's AMRs through MiR's partner ecosystem of over 160 top modules enhancing robot functionality.

Interroll's facility in Switzerland had a multi-floor logistics challenge requiring flexible material transport between production and warehousing. Existing solutions lacked the adaptability for safe, automated multi-floor handling in a dynamic environment.

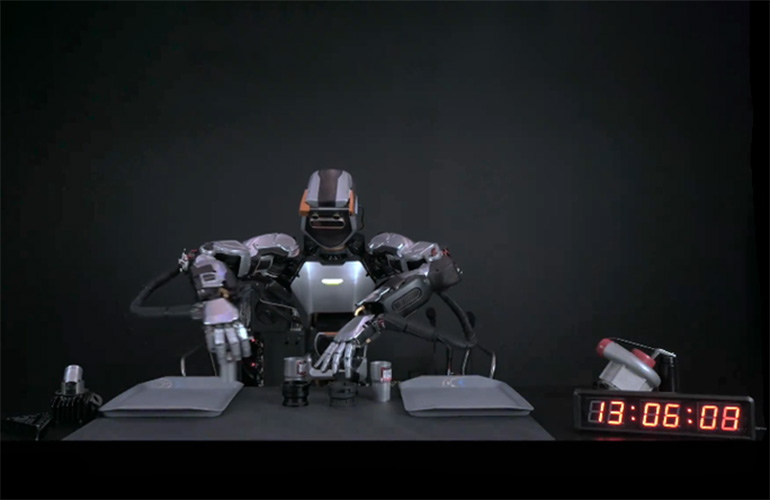

The partnership integrated MiR's AMRs with Interroll's new light conveyor platform (LCP) top module. MiR250 robots autonomously navigate the facility using elevators to connect Interroll's production lines via the conveyor module.

This leverages MiR's adaptable precise navigation and Interroll's seamless production logistics integration. MiR Insights optimizes the solution further, enabling data-driven improvements to the robot fleet's performance and efficiency.

Interroll strategically chose MiR for its market leadership, rigorous testing results, and precise multi-floor navigation. Enhanced workplace safety and automation allow focusing personnel on higher-value tasks.

The combined solution significantly reduced manual material transport times. Interroll anticipates a positive ROI through increased productivity and lower labor costs.

For MiR, this partnership with a respected industry leader like Interroll validates the quality and production integration capabilities of their robots. The flexible connected solution will streamline processes worldwide.

In just over one month, MiR Insights showed the MiR250 operating 22 hours per day, covering over 100km in the facility. This data visibility enables continuous optimization.

This case study demonstrates the power of blending modular automation technologies to adaptively solve dynamic supply chain challenges. As leaders in their respective fields, Interroll and MiR's strategic alliance unlocks new potential for intelligent intra-logistics.